Thermal Management Solutions

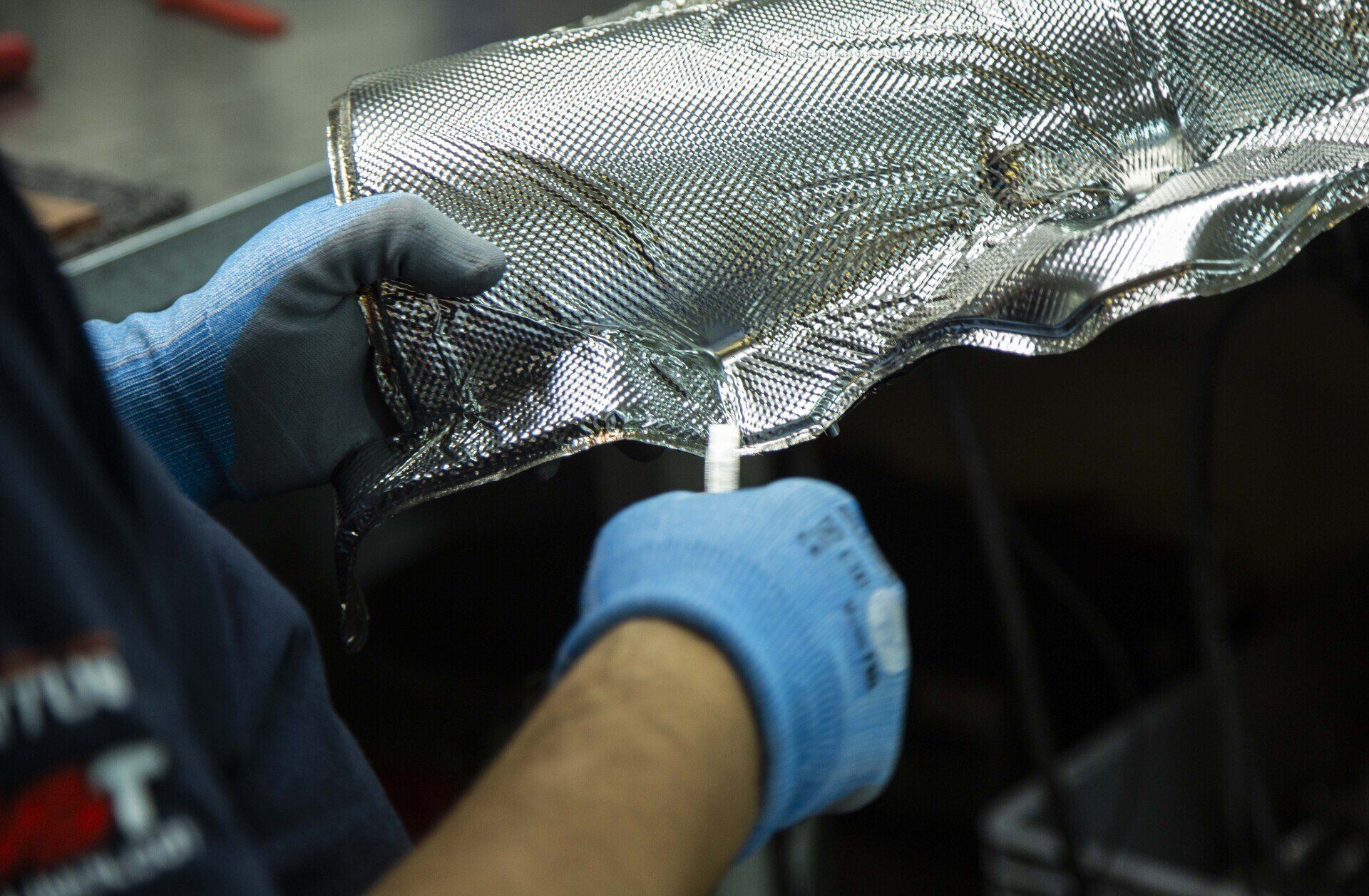

Thermal Cladding & Insulation

Thermal Cladding and Insulation (including integrated heat shields): There are many areas where our high temperature ducts and systems operate in close proximity to heat sensitive components and assemblies.

For these situations, SST Technology has developed a range of thermal management solutions that significantly reduce the heat transfer to the surrounding areas.

The technology involves a thermal barrier material that acts as an excellent insulator and as a high performance barrier to infra-red transmission meaning that these thermal management solutions offer the best performance in the elevated temperature range.

These high performance materials can be applied directly to a duct in the form of a cladding or lagging or as a separate insulating element in the form if a heat shield that can be either a self-supporting element or can be applied to the area that is being protected in the form of an integrated heat shield.

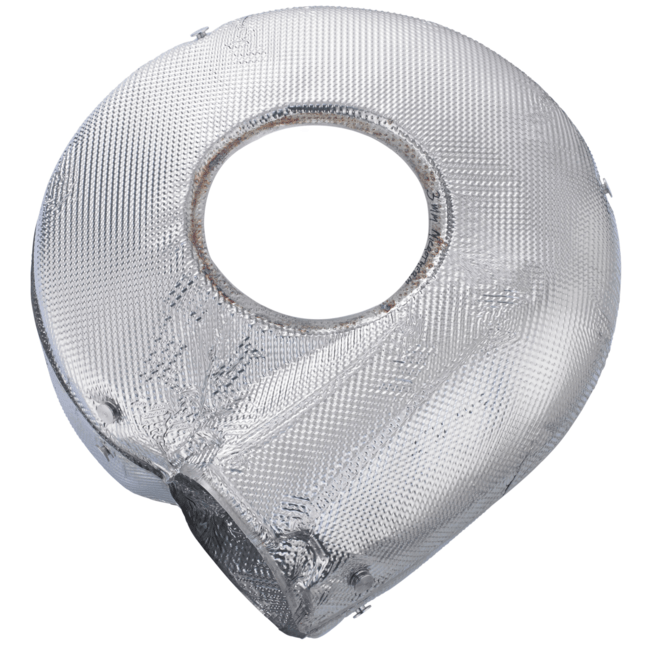

Heat Shields

A combination of industry leading CAD packages enhanced with bespoke in-house design software allows for maximum design flexibility. This supports product and materials development programmes which are proven and tested in the laboratory, on the dyno and on the track.

The heat shields are produced as self-supporting components. These are typically made up of an insulating layer encased in a protective outer covering. Heat shields come in many configurations and can be “clam shells” to cover hot components or complex shaped components to protect heat sensitive elements such as carbon fibre composite structures or electrical components and battery packs.

"Space efficient and light weight insulation solutions are available and are tailored to suit a variety of thermal requirements and packaging constraints."

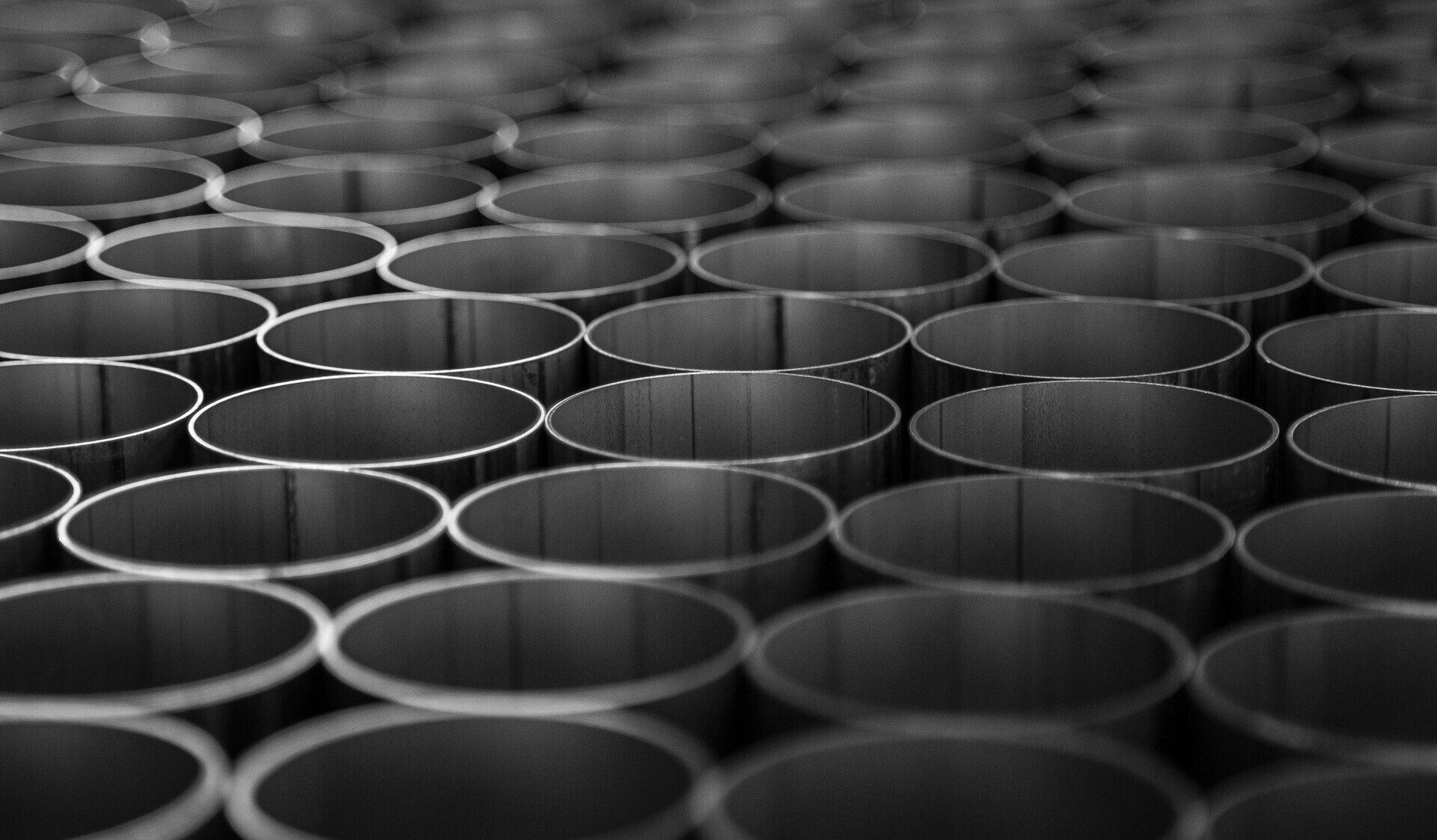

Pipework Assemblies

We design, develop and manufacture a range of high and low temperature pipework assemblies presented in a variety of system configurations to meet most requirements.

Complex pipe geometries with tapered bends and wall thicknesses down to 0.5mm can be achieved. These are manufactured from a variety of metal alloys including Inconel, Stainless Steel, Titanium and Nimonic. The main tubular element can be sourced as bought in tubing or manufactured in house from flat sheet. Ancillary components like flanges, manifold, rings, bosses, housings, springs and clamps are either sourced from specialist suppliers or manufactured in-house to demanding internal standards.

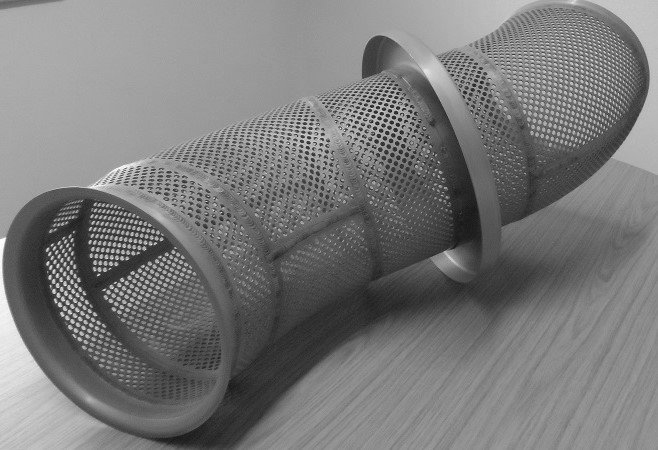

Ducting

SST Technology specialise in the manufacture of ducting for harsh environments where the application may include, high temperature, vibration and corrosive conditions. These ducts are manufactured to the highest standards in accordance to our quality systems and procedures. These components have applications within the power generation industries for the conveyance of hot gasses and in process industries for the transport of corrosive gasses, bleed air ducts, de-icing and low pressure ventilation ducts in the aerospace industry. These ducts form part of complex systems that include manifold components and a wide range of connector geometries.

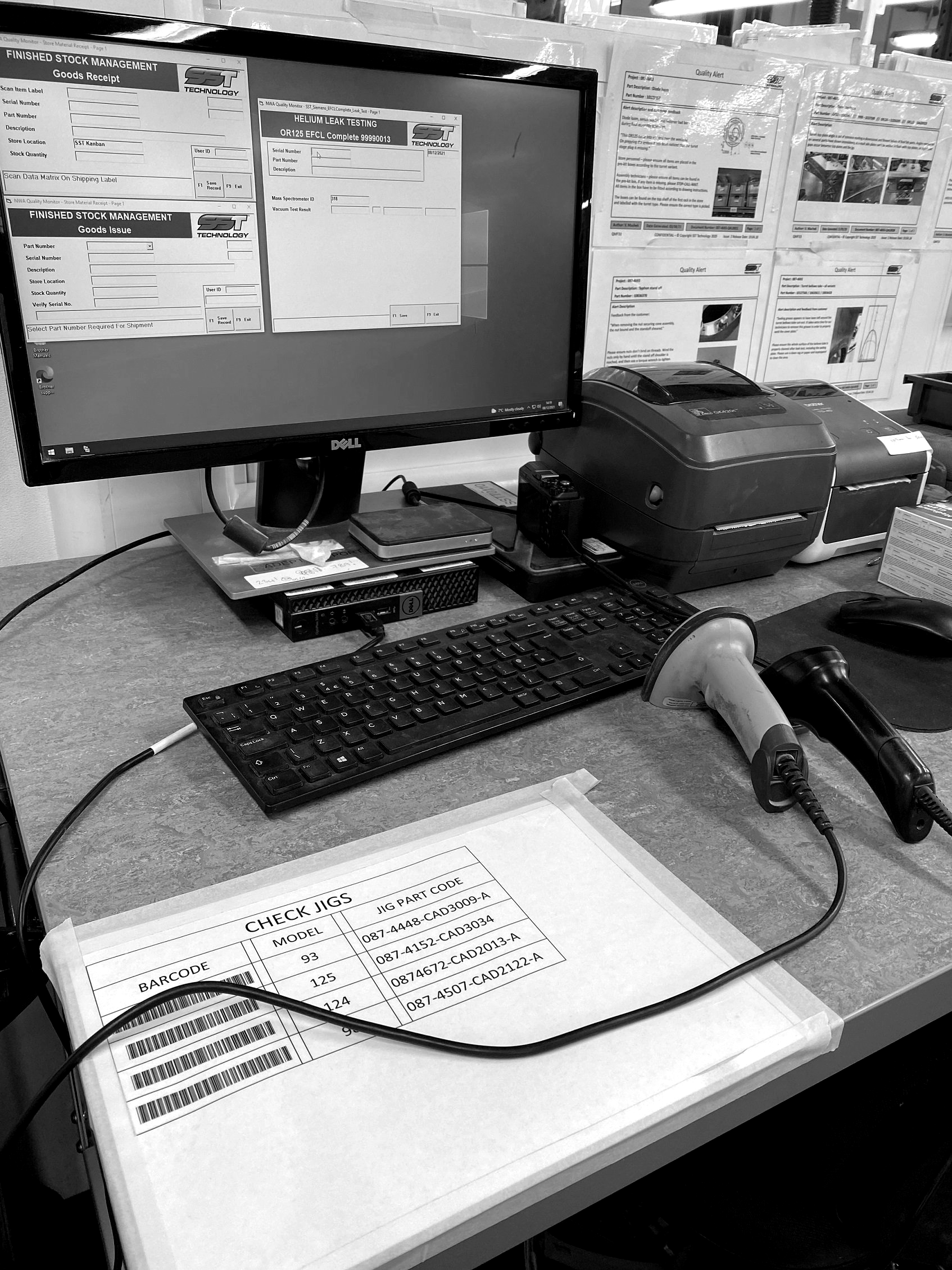

SST Technology is ideally placed to act as a development partner for these parts and is fully equipped to support the design and manufacture of development parts, low rate initial production, volume production, end of programme legacy parts and aftermarket parts.

Find out more about complementary products and services

SST Technology, together with our partner Lentus Composites provide an array of products and services; blending engineering disciplines and techniques to meet our client’s needs.