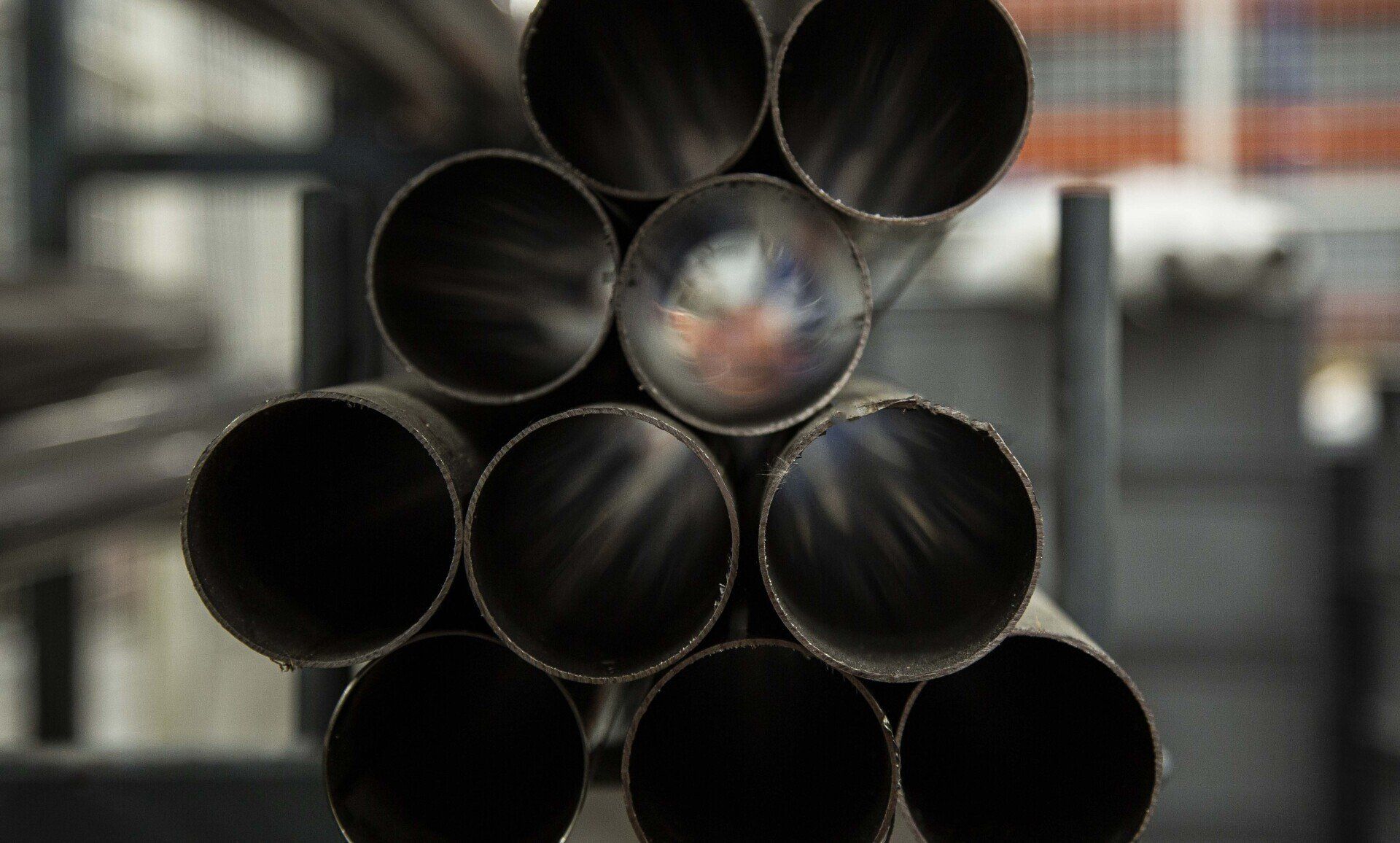

Pipework Assemblies

High Temperature Pipework Assemblies

We design, develop and manufacture a range of high temperature pipework assemblies presented in a variety of system configurations to meet most requirements.

Complex pipe geometries with tapered bends and wall thicknesses down to 0.5mm can be achieved. These are manufactured from a variety of metal alloys including Inconel, Stainless Steel, Titanium and Nimonic. The main tubular element can be sourced as bought in tubing or manufactured in house from flat sheet. Ancillary components like flanges, manifold, rings, bosses, housings, springs and clamps are either sourced from specialist suppliers or manufactured in-house to demanding internal standards.

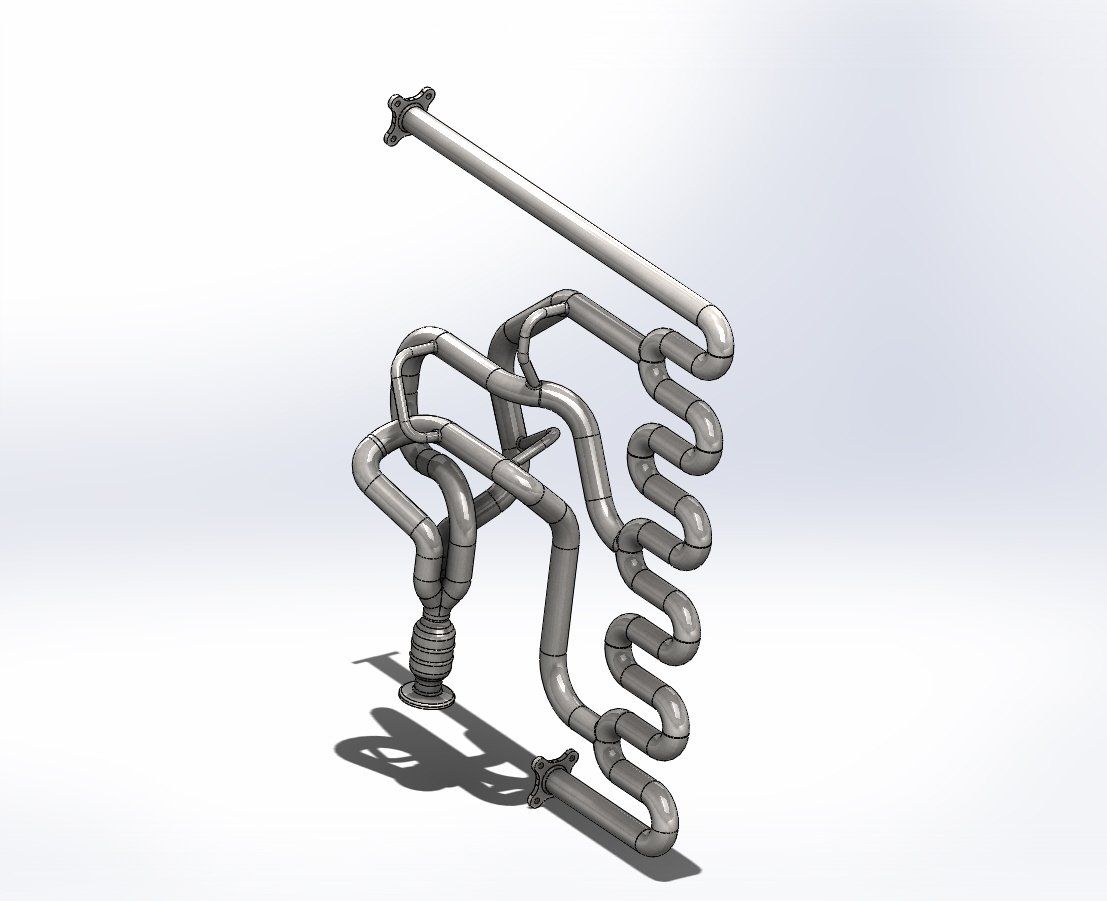

Cryogenic Pipework Assemblies

Cryogenics addresses the science and engineering necessary to produce temperatures of lower than -150 deg C. In industry, cryogenics is used in areas such as scientific discovery, medical imaging devices, food processing, liquefaction and transport of gasses.

SST Technology has the skills to design and manufacture complex pipework assemblies utilising thermal management strategies to deliver bespoke solutions to our customers across these markets. We use highly corrosion resistant cryogenic steel in conjunction with procedures to meet vacuum approved weld standards.

"SST Technology has the skills to design and manufacture complex pipework assemblies utilising thermal management strategies to deliver bespoke solutions to our customers across these markets."

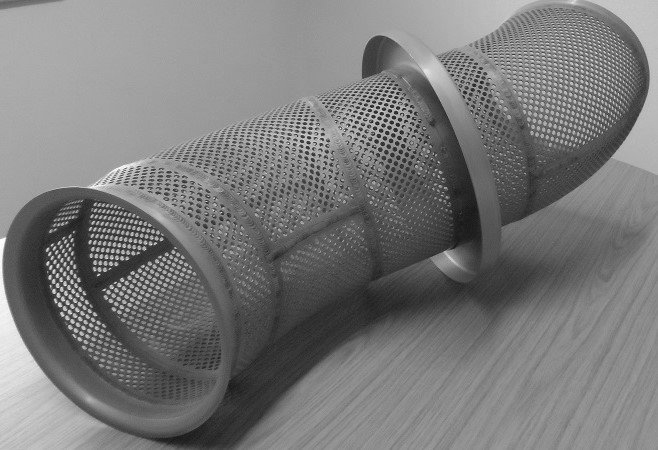

Ducting

SST Technology specialise in the manufacture of ducting for harsh environments where the application may include, high temperature, vibration and corrosive conditions. These ducts are manufactured to the highest standards in accordance to our quality systems and procedures. These components have applications within the power generation industries for the conveyance of hot gasses and in process industries for the transport of corrosive gasses, bleed air ducts, de-icing and low pressure ventilation ducts in the aerospace industry. These ducts form part of complex systems that include manifold components and a wide range of connector geometries.

SST Technology is ideally placed to act as a development partner for these parts and is fully equipped to support the design and manufacture of development parts, low rate initial production, volume production, end of programme legacy parts and aftermarket parts.

Find out more about complementary products and services

SST Technology, together with our partner Lentus Composites provide an array of products and services; blending engineering disciplines and techniques to meet our client’s needs.

-

Project Management

Photo By: John DoeRead More > -

Quality Assurance

Photo By: John DoeRead More > -

Tube Manufacture

Photo By: John DoeRead More > -

Precision TIG Welding

Photo by: John DoeRead More >

Want more information?

UK Office:

Horizon Technology Park, Stanton Harcourt Rd, Eynsham OX29 4GF

Polar Technology Management Group (Company Reg No. 07861070 Registered office: 67 Hightown Rd, Banbury, Oxfordshire OX16 9BE.)

SST Technology

Website Design by Warpspeed Web