UK Office:

Horizon Technology Park, Stanton Harcourt Rd, Eynsham OX29 4GF

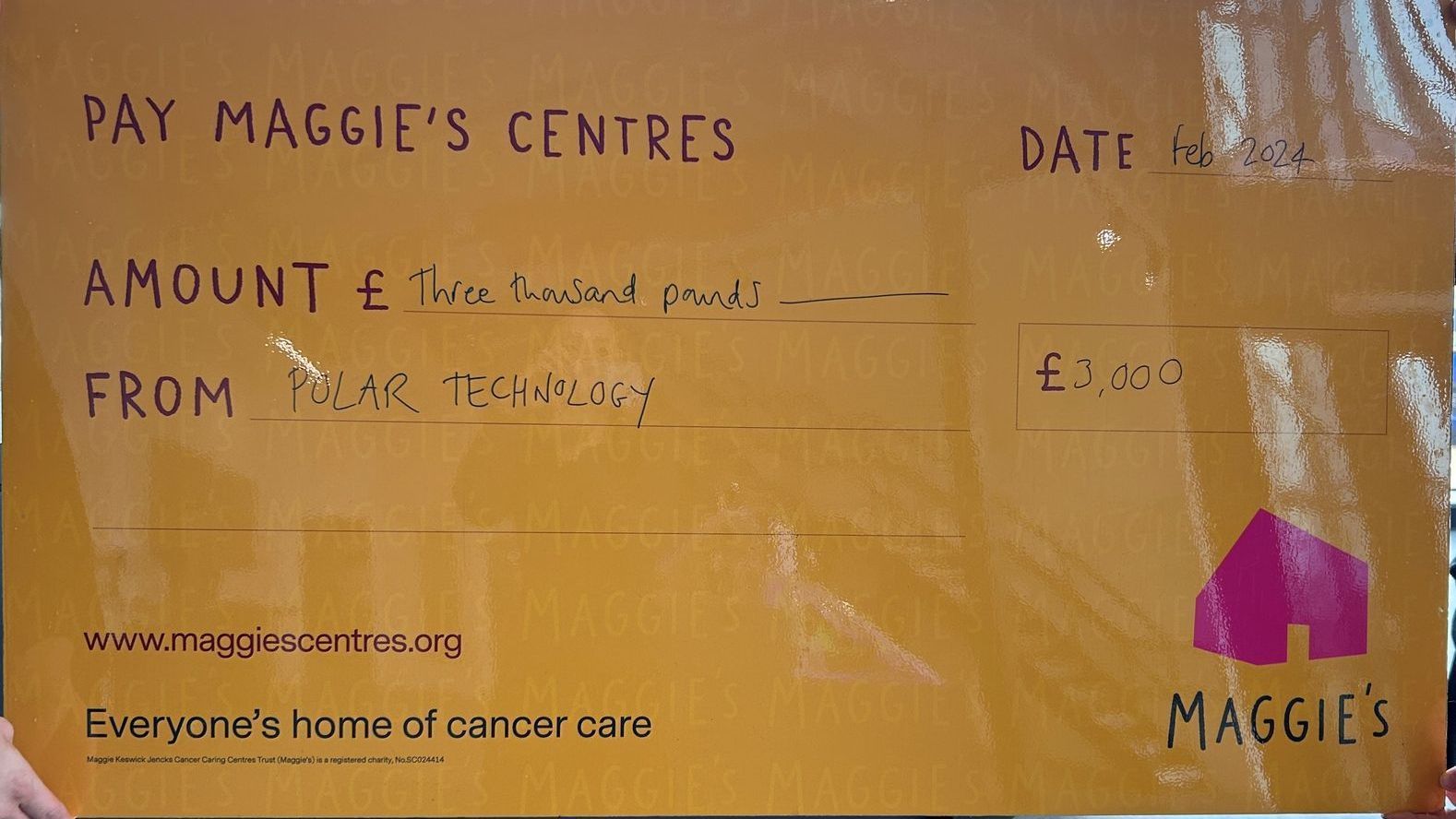

Polar Technology Management Group (Company Reg No. 07861070 Registered office: 67 Hightown Rd, Banbury, Oxfordshire OX16 9BE.)

© 2025

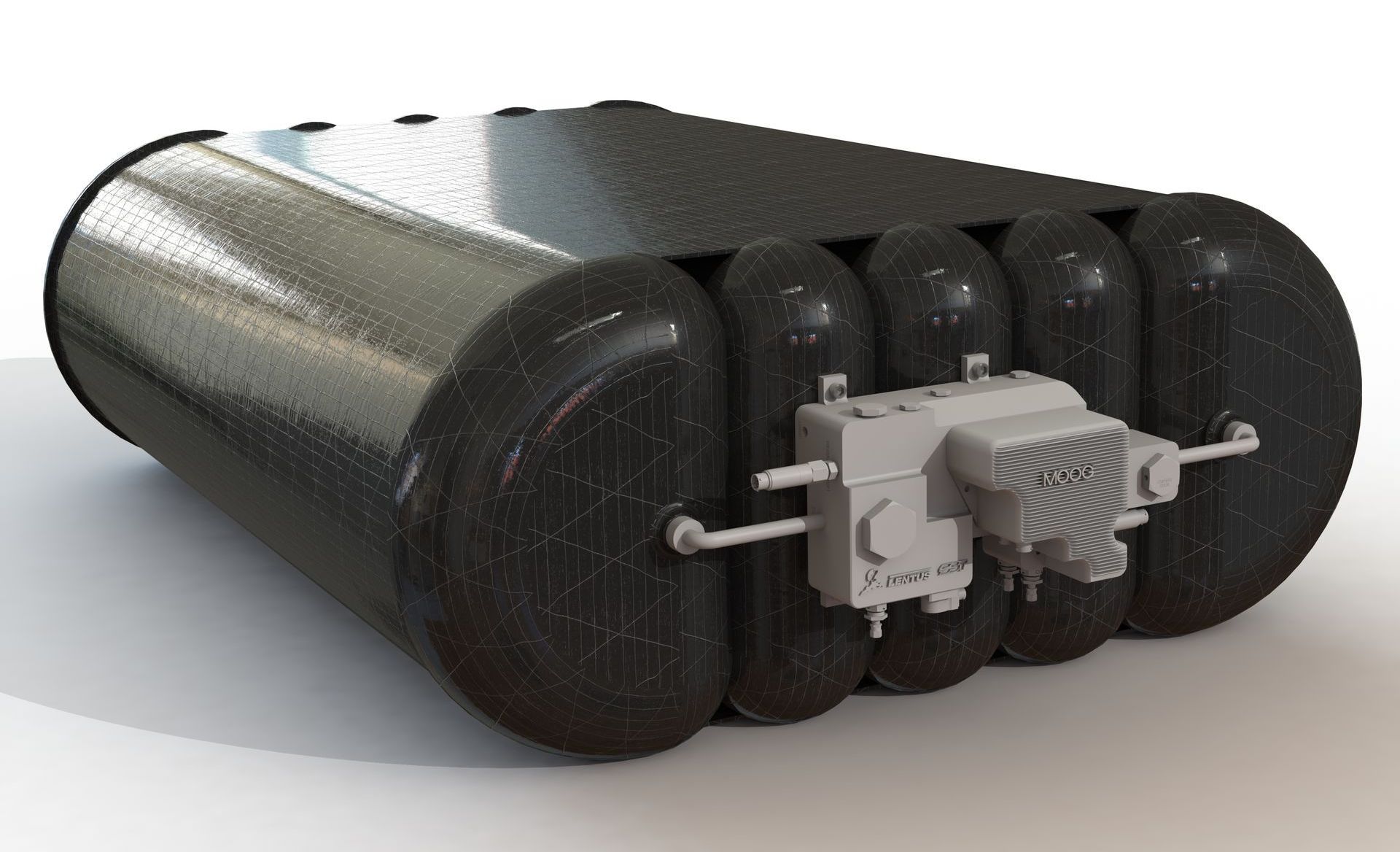

SST Technology

Website Design by Warpspeed Web